Noise barriers are typically constructed on concrete foundations. In many cases, in-situ concrete posts are even required in the appropriate diameters. Constructing them is time-consuming and cost-intensive. A completely different, yet much more innovative and economical foundation system was recently used in constructing a noise barrier near a park and ride lot in Bad Hersfeld: steel root foundations that use no concrete at all. SteelRoots® is the name for the new foundation system constructed of steel elements, developed by the company BFtec from Nentershausen-Süß.

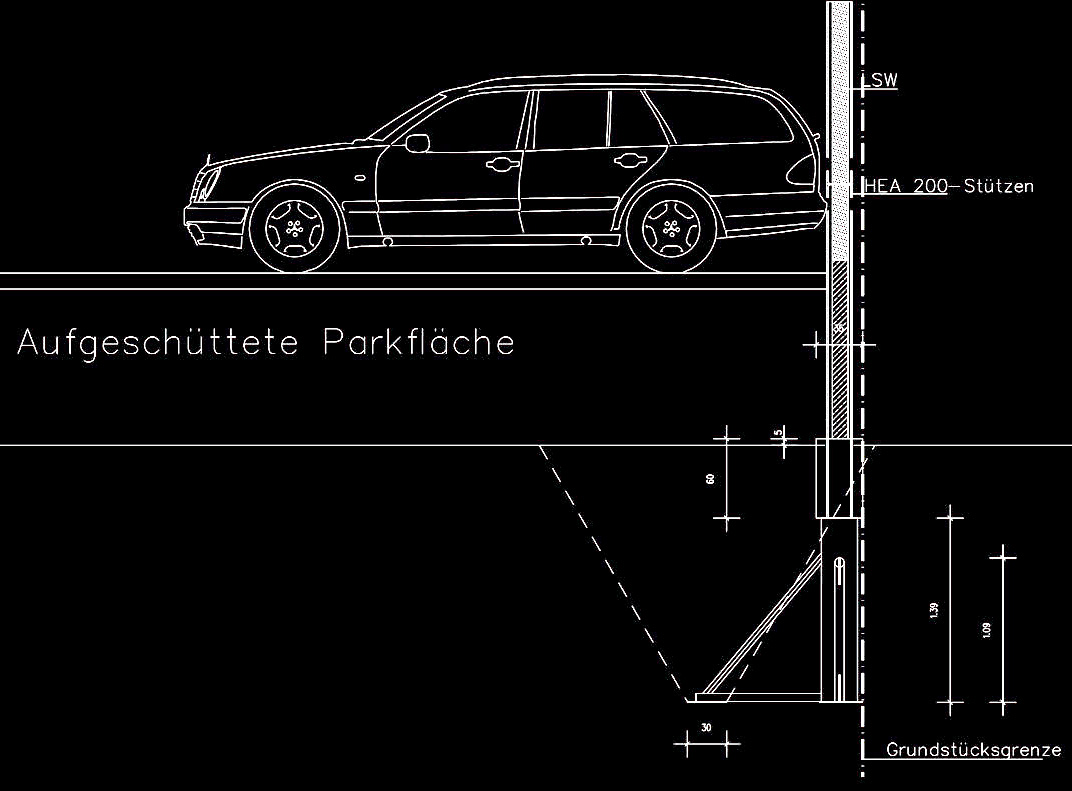

A directly adjacent neighboring building, a height offset of 1.30 meters, high traffic loads and non-homogeneous soil conditions – these were some of the challenges that faced workers at the Räuber construction company in building a roughly 70 meter long sound barrier at the edge of the P+R parking lot, near the Bad Hersfeld train station. The fact that the responsible construction manager, trained engineer Mathias Wagner, chose a SteelRoots® foundation from BFtec as the most economical solution was no accident. Instead, his choice was based on past positive experiences – the traditional Bad Hersfeld company had already used the new SteelRoots® foundation system successfully in spring 2018 for a steel commercial hall in the Hauneck district of Unterhaun. Cost-efficiency, a high level of flexibility, and easy assembly of the system ultimately caused the municipality to choose the system over a traditional foundation for that project. Another important argument for SteelRoots® over concrete foundations is the significantly shorter construction time: The setting time for concrete, which can easily be between 21 and 28 days depending on the size of the foundation, is eliminated. SteelRoots® can also be installed at almost any time during the winter months.

However, the small amount of space available at the Hersfeld train station required some adjustments to the SteelRoots® construction: Instead of being placed on four feet as usual, the load had to be borne by just three. Another complicating factor was that the foundation needed to handle much higher traffic loads, due to the adjacent parking areas. There was also one more requirement to fulfill before work could be carried out: The SteelRoots® needed to be connected to the same type of sleeve where the other load-bearing elements for the sound barrier were placed. The proven work processes used to construct the sound barriers, however, needed to stay the same.

BFtec founder Peter Kellner and his team had the right solution for these unique requirements. They turned a “+” into a “T. An illustration might help here: if you look at a SteelRoot® from above, it looks like a plus sign. The four struts are aligned at exactly 90 degree angles to one another. For the construction project at the Bad Hersfeld P+R facility, one of the SteelRoot® supports was removed, and one side was lengthened significantly. This created a T shape. The structural capabilities of this special design were calculated according to standard engineering practices by engineer Ditmar Halm, consulting engineer at IK-Bau Nordrhein-Westfalen (Construction Engineering Chamber of North Rhine Westphalia), and structural calculations were reviewed by engineer Bunje at the construction engineering firm of FEHLING+JUNGMANN GmbH in Kassel.

The SteelRoots®, weighing 360 kilograms, were transported to the construction site in individual pieces and assembled on site. Employees at Räuber certainly benefited from the experience gained during construction of the new warehouse in Hauneck, but in principle assembly with SteelRoots® was just as quick and simple as usual: The individual elements are easy to put together and only fit in one direction. A roughly 3 x 2 meter large pit was excavated for each SteelRoot®, the soil was stored on the construction site, a subgrade was constructed, and the SteelRoot® was lifted into place using an excavator. Then the pits were filled again with the saved soil and compacted layer by layer. Similar to counterweight foundations, with SteelRoots®, the soil surrounding the steel roots is used to carry the load. Civil engineering specialists set 19 steel roots foundations in one week.

The steel sleeve was screwed to the top segment of the SteelRoots®, creating a positive-locking connection with the struts of the sound barrier. To compensate for the height difference on both sides of the sound barrier and the high traffic loads on adjacent parking lots, precast concrete parts were initially set as supporting walls between the roughly 4 meter long steel struts. The elements of the sound barrier were then mounted on these.

According to construction manager Mathias Wagner, constructing a foundation with SteelRoots® made it possible to eliminate soil replacement and complex in-situ concrete post foundations in such a narrow space. Instead, SteelRoots® offered a foundation option that could be constructed more quickly while also being less expensive.