STEEL-ROOT® are also an economical alternative to any foundation on steel pipe or reinforced concrete piles for the foundation of noise barriers - especially in confined spaces where heavy drilling equipment cannot be used. Even the soil does not have to be disposed of, but is reused for filling the STEEL-ROOT®.

as foundations for noise barriers

as foundations for noise barriers

STEEL-ROOT® are also an economical alternative to any foundation on steel pipe or reinforced concrete piles for the foundation of noise barriers - especially in confined spaces where heavy drilling equipment cannot be used. Even the soil does not have to be disposed of, but is reused for filling the STEEL-ROOT®.

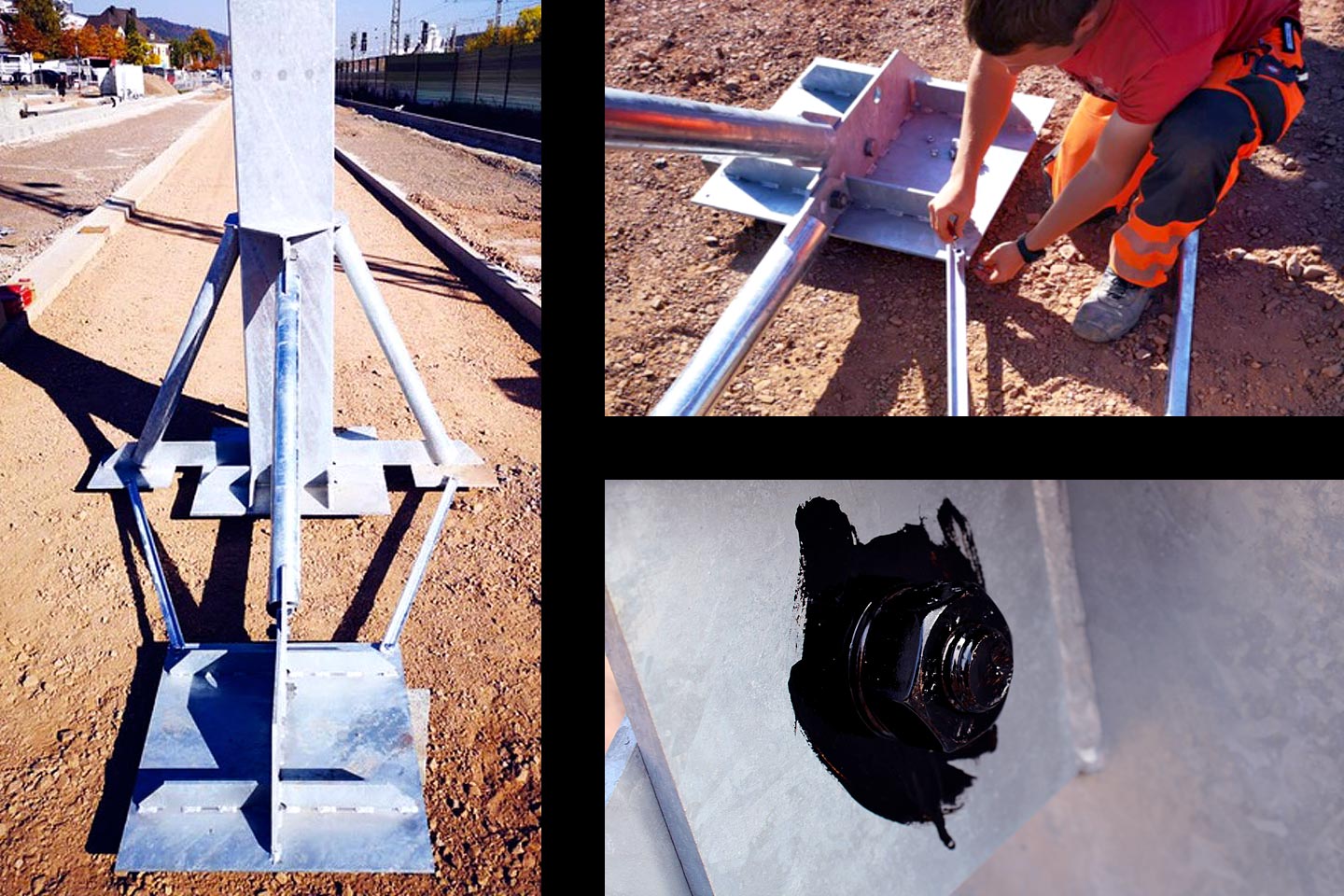

Below you can see an installation example of a noise barrier with the help of STEEL-ROOT® foundations:

This STEEL-ROOT® version was specially developed for these noise barriers. The difficult ground conditions, a height offset of 1.3 meters plus the border building would not have been economical with a conventional foundation solution.

Excavation of the construction pit. On-site storage of the excavated soil.

Creation of the planum.

The STEEL-ROOT® foundation can be easily assembled outside the construction pit. Additional protection of the connections.

The fully assembled STEEL-ROOT® foundation is lifted into the construction pit and aligned afterwards.

Then the old soil is backfilled and compacted layer by layer. The installation of the STEEL-ROOT® foundation itself is completed now. The STEEL-ROOT® foundation can be loaded immediately, therefore you can proceed with the installation of the noise barriers.

Quiver for receiving the noise barrier elements. Inserting and aligning the steel girders to receive the concrete elements. Pouring the upper quivers with special concrete.

Concrete elements are getting inserted. Filling at ground level.

Also noise barriers can be realized with STEEL-ROOT® foundations — especially in confined spaces where heavy drilling equipment cannot be used.